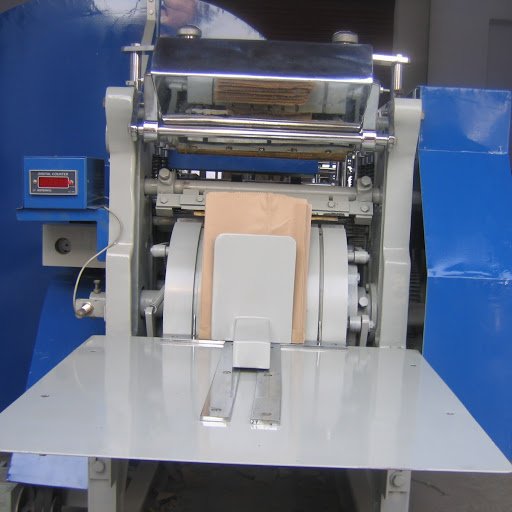

Paper Bag Making Machine

PAPER BAG MAKING MACHINE IS DESIGNED TO MANUFACTURE FLAT AND SATCHEL PAPER BAGS FROM KRAFT PAPER, GREASEPROOF, WHITE PAPER AND POSTER PAPER ETC. IN DIFFERENT SIZE FOR PACKING CONFECTIONERY, FOOD STUFF, READY-MADE GARMENTS, TOBACCO, TEA POWDER GROCERY, DRY CLEANERS ETC

Our Paper Bag Making Machines are successfully working Overseas in Palestine, Lebanon, Saudi Arabia, Uganda, Ireland, Egypt, Morroco, Kuwait, Chile Etc.

Paper Bag Making Machine is Made of rigid and Robust Construction to Avoid Vibration. All Paper are Arranged in Most Accessible Way Thus Making Operation and Adjustment Very Simple and Quick So That Even an Unskilled Labour Can Easily Operate the Machine Successfully. The Change of Size is Very Easy And Can be Done in Few Minutes Time. The Machine is Supplied with One Size Plate and One Size Gears to Manufacture One Size of Paper Bag. Different Size Plates & Size Gear For Flat And Stachel Bags Are Available At Extra Cost. Mill Reels Upto 34†Dia and 34†Width Can be Accommodated of the Machine. The Width of the Paper Reel to be Fed on the Machine Can be Calculated as Under.

Flat Bags : Flat Bags Twice the Bag Width Plus 2 CM for Centre Seam.Satchel Bags Twice the Bags Width Plus 4 Time Depth of the Gusset Plus 2 CM For Centre Seam.

Bag Formation : The Required Size of the Bag us Obtained by Fixing The Exact Size Plate For Flat or Satchel to the Size Plate Holder And the Length to the Tube Is Obtained by Changing the Size Gear Wheel, Each Tooth of Which , Represents One Centimeter in Length, The Tube After Being Cut by the Beater Into Exact Size As Per the Size Gear is Carried Forward By Means Of Conveyor Rollers to the Delivery Cylinder the Delivery Cylinder As the Bottom Fold Is Made is the Bag it is Pasted and the Bag is Carried by the Folding Cylinder to the Delivery Table Where it is Released and Delivered in a Vertical Stack.

Printing Attachment: Our Two or Four Colour Flexo Printer Can Be Coupled With the Paper Bag Making Machine.

Specifications of Paper Bag Making Machine

| Model | Large | Medium | Standard | Baby |

|---|---|---|---|---|

| Max. Size of Bag | 42cm x 60 cm | 28cm x 50cm | 26cm x 36 cm | 15cm x 22 cm |

| Min.Size of Bag | 12cm x 18 cm | 12cm x 18 cm | 5 cm x 10 cm | 5 cm x 10 cm |

| Capacity per 8Hr. | 50-60,000 bags | 60-70,000 bags | 70-80,000 bags | 80-90,000 bags |

| Flexo Printing | 2,3,4 Colours | 2,3,4 Colours | 2,3,4 Colours | 2,3,4 Colours |

Paper Bag Creasing Machine

Paper bag creasing machine is used for creasing bag top and bottom to make square bottom paper bag by hand. Machine is made up of isi angles and cast iron body with vibration free performance.

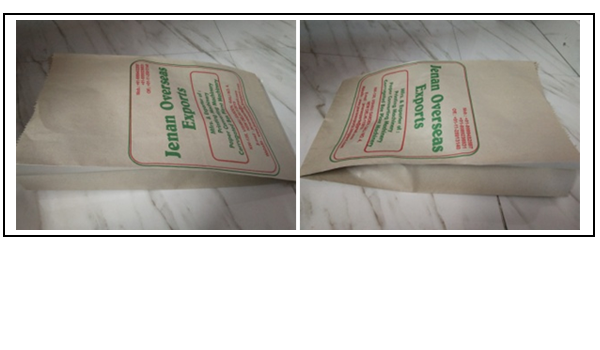

Before Creasing Paper Bag.

After Creasing Paper Bag

After Creasing Paper Bag

Eyeleting Riveting Machine

We offer Eyeleting Riveting Machine. These machines are lightweight and compact and are catering to the requirements of Paper Bag, medical, automotive etc.

Paper Bag Creasing Machine

Paper bag creasing machine is used for creasing bag top and bottom to make square bottom paper bag by hand. Machine is made up of isi angles and cast iron body with vibration free performance.

Flexibility

We understand that our clients’ tastes are different and that they would require different sizes of bags at different times. The blade and gear adjustments of our machine make the process of creating bags look very easy and simple.

High quality

Jenan Overseas Exports handmade paper bags may get damaged due to a slight human error at times. However, in the case of paper bag making machines, there is no chance of error at all as the settings are pre-set, and the process is 100% automatic.

Low maintenance

Paper bag machines run on electricity, but the good thing is that they don’t consume a lot of power. Also, our machines are very well-maintained; therefore, they don’t breakdown frequently. Most of the paper bag machines across the world use very good technology.

Time cost savings

A paper bag machine, on the other hand, saves you a lot of time as they use sophisticated cutting and designing tools to create tailor-made bags to suit your requirements.