Time cost savings

A paper bag machine, on the other hand, saves you a lot of time as they use sophisticated cutting and designing tools to create tailor-made bags to suit your requirements.

Flexibility

We understand that our clients’ tastes are different and that they would require different sizes of bags at different times. The blade and gear adjustments of our machine make the process of creating bags look very easy and simple.

High quality

Jenan Overseas Exports handmade paper bags may get damaged due to a slight human error at times. However, in the case of paper bag making machines, there is no chance of error at all as the settings are pre-set, and the process is 100% automatic.

Low maintenance

Paper bag machines run on electricity, but the good thing is that they don’t consume a lot of power. Also, our machines are very well-maintained; therefore, they don’t breakdown frequently. Most of the paper bag machines across the world use very good technology.

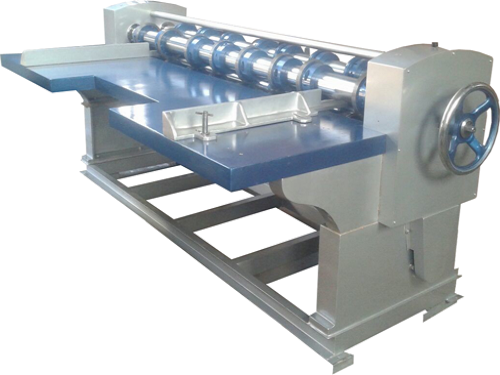

4 Bar Rotary Cutting and Creasing Machine

Four Bar Rotary Cutting and Creasing machine is useful for creasing and cutting simultaneously. The machine is with two pairs of shafts. The front pair is with cutting dies and rear pair is with creasing die. The lower shaft of each pair can be raised or lowered by revolving side wheel. For easy feeding two guides are provided.

| TECHNICAL DATA | |||||

| Size | CAPACITY | MINIMUM DISTANCE | POWER REQUIRED | FLOOR SPACE | GROSS WEIGHT |

| BETWEEN TWO DIES | |||||

| 65'' | 300 | 3'' | 1.5 H.P | 85''X52'' | 1700KG |

| 75'' | 300 | 3'' | 2 H.P. | 98''X52'' | 2100KG |

| 85'' | 300 FT/MIN | 3'' | 2 H.P. | 110''X56'' | 2300KG |

| 95'' | 300 | 3'' | 2 H.P. | 120''X60'' | 2500KG |

| 105'' | 300 | 3'' | 3 H.P. | 130''X60'' | 2700KG |

| 125" | 300 FT/MIN | 3" | 3 H.P. | 150''X70''150''X70'' | 3200 KGS |